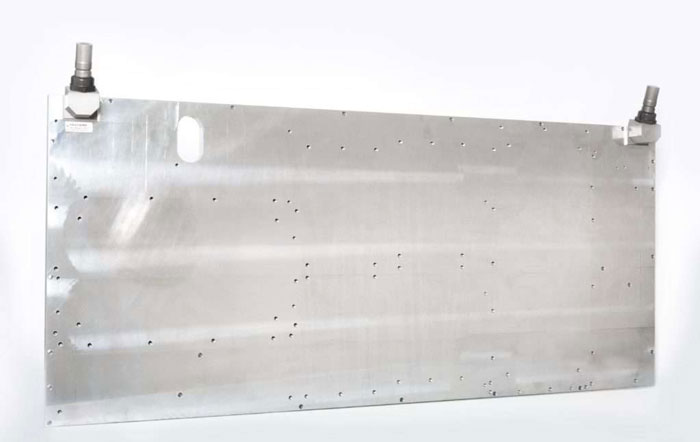

PT Zed – Liquid Cold Plates

Liquid cold plate consisting of a base and a cover, sealed via brazing technology.

When air cooling no longer achieves the desired thermal performance, liquid cooling solutions are the answer. In fact, the heat transfer coefficient of water is much higher than for air.

These are LCPs that are part of a liquid cooling system consisting also of: heat exchanger, a pump (which moves the liquid), and a tank (which stores the liquid). The liquid cold plate is a component in direct contact with the heat source.

PT Zeds are built starting from an aluminum plate with grooves, made via mechanical processing, through which the cooling fluid (a mixture of water and glycol) flows. We use our brazing technology to attach an aluminum cover to the base, which seals the grooves, creating a metal joint between the base and the cover.

The result is a single structure with considerable advantages:

- no o-ring is required, as the joint between base and cover is metal;

- great flexibility in designing the grooves, which can be positioned directly under heat sources;

- if made of aluminum, the connectors can be brazed directly onto the plate;

- more compact and higher performing solution compared to an air heat sink