Introduction

A medical laser – or a surgical laser, depending on its intended use – is a device which, following the excitation of an amplifier medium, makes it possible to generate a beam of coherent and monochrome photons with the same phase and wavelength. In fact, ‘laser’ stands for ‘Light Amplification by Stimulated Emission of Radiation’.

The generated beam is an electromagnetic wave with a characteristic wavelength, amplitude and duration of emission (pulses). These features determine the power of the laser and, based on the characteristics of the tissue to which it is applied, also determine the penetration depth at which the laser will be absorbed and its applications.

Low and High-Power Broadcasting Transmitters with Air and Liquid cooling, featuring all analog and digital worldwide broadcasting standards

Application field

Lasers have been used in everyday clinical practice in several fields of medicine for quite some time:

- The fields of medicine that use lasers the most are dermatology and aesthetic medicine. In these fields, they are used for removing tattoos, for permanent hair removal, for treating acne, and for skin rejuvenation and toning.

- Lasers are used in urology for the enucleation of the prostate and have been used extensively in ophthalmology as well, especially for refractive surgery in order to treat a number of conditions, including myopia, astigmatism, hypermetropia and presbyopia.

- Another medical field in which lasers are used is General Surgery, for soft tissue ablation. Laser treatment is also being used more and more frequently in dental practices.

This kind of machinery needs to be compact (small in size), quiet (noise can be a problem as it can decrease patience levels), efficient and reliable (it needs to be safe and accurate in the long term as we are talking about people’s health).

Cooling plays a key role, since a large amount of heat from the core of the laser needs to be quickly and safely dissipated.

The challenge

The customer got Priatherm involved in redesigning a product family of state-of-the-art medical lasers. A new high-performing laser was introduced, with the following specifications for the heat sink:

- reduced size and a customised design so that it can be contained in beautifully designed carpentry – since it is a portable machine, its weight had to be as low as possible;

- a high level of performance combined with low forced ventilation (use of a low-noise fan);

- relatively cheap for medium to large-scale mass production.

Solution

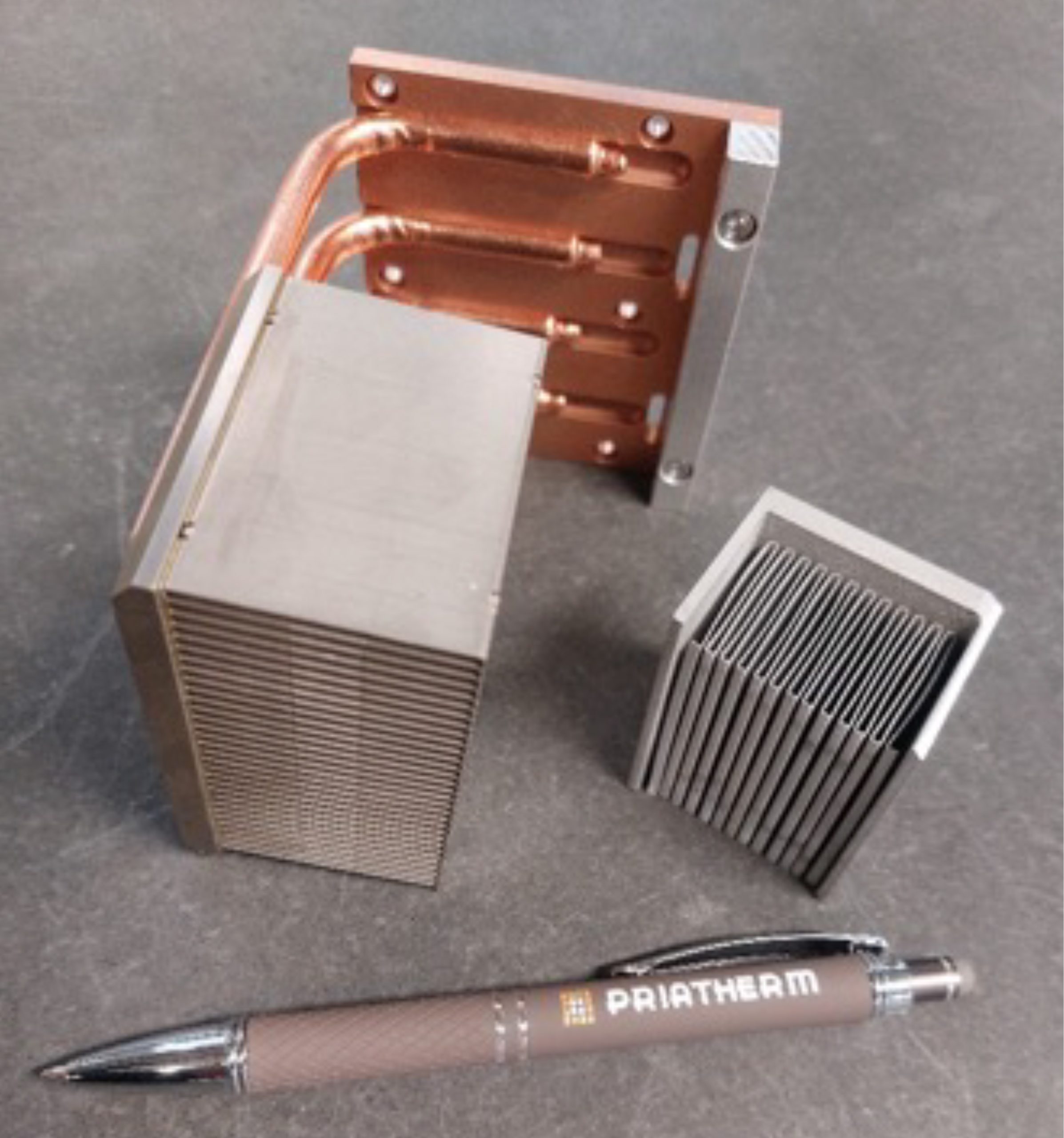

The project was designed so that two different heat sinks could be created in order to cover the entire range of machinery, with higher powers to be dissipated.

- Low-power heat sink: small PT High, with brazed folded fins as a cooling fin pack

- High-power heat sink: Heat pipe system, with hinged welded fins as a cooling fin pack.

Priatherm harnessed its expertise and technology in order to come up with the best possible solutions.

In order to do this, it identified and mapped hot spots with CFD thermal simulations, while forced ventilation was kept as low as possible so as to choose the simplest fan.

Various materials (aluminium and copper) and joining methods (brazing and welding) were used to produce them. The goal was to reduce the overall size and weight as much as possible while continuing to ensure maximum thermal efficiency!

Top challenges

-

High performance Vs compact overall dimensions

-

Solved the issue of reduced weight and noise