Priatherm

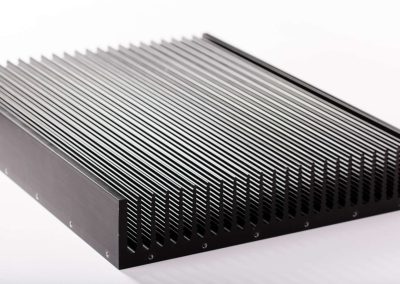

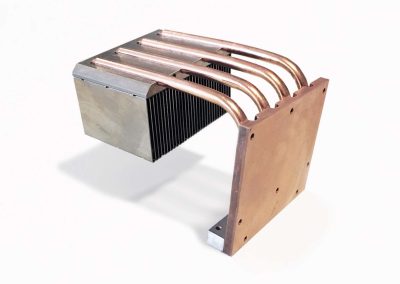

Engineering and manufacturing custom thermal management solutions is our specialization.

Led by industry know-how and an innovative product approach, Priatherm has become rapidly a key player in the European heat sink market with a focus on high power thermal management.

About Us

Overview

Priatherm provides effective solutions in a broad range of high power density electronics applications; we supply locally whilst ensuring superior product quality and customer support.

Quality is an essential item for the continuous success of Priatherm: a Total Quality Management approach where every shareholder, employee, supplier, partner, manager, public organization, member of local community and customer is considered an essential part of our processes.

Mission

“Being one step ahead in engineered thermal solutions for the Power Electronic industry”

Our business processes are designed to create and add value for our customers by leveraging our in- depth market knowledge and offer:

> Innovative solutions for demanding applications

> Faster time to market approach through enhanced flexibility

Our commitment is to be the thermal solutions Partner of choice.

Vision

We provide superior products and services that meet or exceed customers’ present and future expectations, at an attractive price and by means of continuous improvement and innovation.

We strive to achieve Excellence by adopting and maintaining:

> Company Management System in compliance with ISO standards for Quality, the Environment, Health & Safety and international regulatory requirements.

> An error-free performance standard, based on prevention and a ‘right-first-time’ attitude.

> A culture that is open to changes, to challenges and to innovation, careful to environmental performances.

> Policy of continuous improvement in business performance, processes, as well as products and services.

> Commitment to develop personnel through training at all levels of the company’s operations.

What we do – Know How

Brazing & Assemblies

From design to final testing, our experts can design and build any type of optimized heat dissipation solution whether it is air or liquid dissipation. The production takes place, thanks to controlled atmosphere ovens, using the brazing technology (Nocolok® process) which is considered the best welding method tested in the field.

Services

Priatherm knows the need and importance of thermal management for its customers. In fact, it’s able to provide tailor-made services for each application, guaranteeing the necessary support during the entire process to meet every requirement. We can offer services and consultancy such as:

Fluid Dynamics Analysis

Prototyping

Testing Capabilities

Applications

Quality Management System

Priatherm aims to provide, with the commitment of each member of the company, products and services that meet or exceed current and future customer expectations, at a competitive price and by means continuous innovation and improvement.

“Commit to do well today,

to do even better tomorrow”

Total Quality Management

Every shareholder, employee, supplier, collaborator, manager, institution, community member and customer is considered part of our processes.

Corporate Management System

Implementation and maintenance in compliance with ISO standards for quality and international regulatory requirements.

Striving for excellence

An error-free performance standard, based on prevention and a ‘right-first-time’ attitude.

Culture open to changes

As well as to new challenges and sustainable innovation.

Continuous commitment to improvement

In business performance, processes, products and services.

Personnel development

Through training activities at all levels of the company.

Total Quality Management

Every shareholder, employee, supplier, collaborator, manager, institution, community member and customer is considered part of our processes.

Corporate Management System

Implementation and maintenance in compliance with ISO standards for quality and international regulatory requirements.

Striving for excellence

An error-free performance standard, based on prevention and a ‘right-first-time’ attitude.

Culture open to changes

As well as to new challenges and sustainable innovation.

Continuous commitment to improvement

In business performance, processes, products and services.

Personnel development

Through training activities at all levels of the company.

Media & News

Download your free copy of our e-book:

“Heat Pipes Product Guidelines”

Or go to previous e-books

Satisfied Clients

Where We Are

Head Office

Via Gherardo Monari, 34

44124 – Ferrara – Italy

Phone: +39 0532 1930289

E-Mail: info@priatherm.com

Registered Office

Via della Solidarietà, 2/1

40056 Crespellano,

Valsamoggia (BO) – Italy

Get in touch

Priatherm is a company of

Cocchi Technologies is an industrial group devoted to innovation, technology and growth. Established in the 90s by Gino Cocchi, today CT consists of 14 companies that employ more than 800 people worldwide, representing more than 33 nationalities. Manufacturing in Italy, Germany, France, Switzerland, Mexico, the U.S. and China; commercial and technical centers in more than 12 countries; and sales in over 100 countries.