Introduction

- Laser industry

- Inverters for Wind and Solar Energy

- Battery chargers

- Industrial drives

The Customer

- Automotive – where Laser Welding can be used to weld roofs and other components; Laser cutting, for cutting of components and cutting-out of bodywork details in final production;

- Aerospace – Welding using lasers results in reduced weight, better fuel economy, and a smaller environmental impact;

- General industry – where companies contact them to solve problems related to Quality, Costs requirements, and surface finishing

The challenge

We could collaborate on a new project that started with the mechanical engineer involving us in the design of a liquid cold plate, to be inserted in a forced convection cooling system.

Its function was to cool down their tool from the radiation of a laser station.

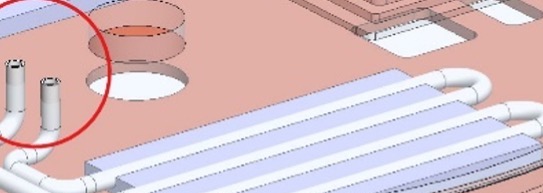

The initial concept was based on our PT Pipe, and the particularity was the desired shape.

The customer wanted it circular, with a copper pipe based on it, and with a particular bending. But, being at the initial heatsink design phase, they were was open to different options.

After a brief feasibility analysis, our Thermal management expert gave us a positive response, and we started with an approximate heatsink design.

In the meantime, our Sales account visited the customer at their headquarter to get more detailed information about the project and to discuss deeply the alternative solutions we could propose.

This has been useful for the final customer opening to the possibility of using stainless steel pipes instead of copper pipes.

The initial customer idea

Solution

The possibility to use stainless steel pipes instead of copper pipes provided many advantages to us.

Even though copper has a better Thermal conductivity compared to stainless steel, negative points need to be mentioned:

- Cost: copper has a higher cost than stainless steel

- Workability: Copper is much more fragile than stainless steel

- Impossibility of being Brazed: with Brazing technology, we can create a metal joint between the channel in the plate and the pipe itself.

Using our specific Nocolock brazing process, it’s impossible to create a metal joint between Copper (of the pipe) and aluminum (plate), because it wouldn’t reach the necessary temperature to melt both of them. The only way to fix them is to use an Epoxy resin (reducing its thermal performance).

On the other hand, brazing between a stainless steel pipe and an aluminum plate is possible. This can guarantee 100% contact between them, which can be translated into a great heat transfer.

Thus, we got a clearer idea of the possible solution and we asked for the definitive boundary conditions, in order to proceed with a Thermal simulation.

Conditions were the following:

- 1/1.5 kW needed to be dissipated (all over the shield)

- The flow rate is maximum 24 liters/min, but they were planning to use 7 liters/min

- Deionized water as coolant

- Aim for an inlet temp at 20°C deg and a hotspot on 50°C

Thermal simulation results satisfied the customer‘s request, but little details needed to be managed.

After a technical explanation about the thermal distribution, the customer was satisfied and proceeded with the Critical Design Review, a phase in which the end customer went through the design and approved it for manufacturing.

As promised, in a couple of weeks we received the Purchase Order and started the production respecting the scheduled Lead Time.

Months later, following the test phase on the Laser Machine, the customer informed us the liquid cold plate was working efficiently.

A section of the final LCP

Top challenges

- The curved shape of the pipe – it was one of the hardest parts, but thanks to our pipes supplier, we have been able to recreate what the customer was demanding

- Convincing the customer to change their first idea – it’s always hard to change it, but after showing the advantages our solution could offer, they accepted our suggestions

- Maintaining steady communication over several months and being flexible – this project ran over almost 12 months, with uncertainty from the customer’s side. Despite all this, Priatherm always showed to be flexible and available for any support.